Ihr Warenkorb

| Beschreibung | Teile-Nr. | Anzahl |

|---|

15. REAR WHEEL/AXLE/SUSPENSION/

DRIVING MECHANISM MXU 300/250

REAR AXLE INSPECTION:

Check the axle splines for wear or damage.

Set the axle in V-blocks and measure the

runout with a dial indicator.

Axle runout is 1/2 the total indicator reding.

Service limit: 3 mm (0.12 in)

FINAL GEAR CASE INSPECTION:

Turn the pinion gear and check that the gear

turns smoothly and quietly without binding.

If the gears do not turn smoothly or quietly,

the gears and/or bearing may be damaged or

faulty. Replace the final gear case assembly

if necessary.

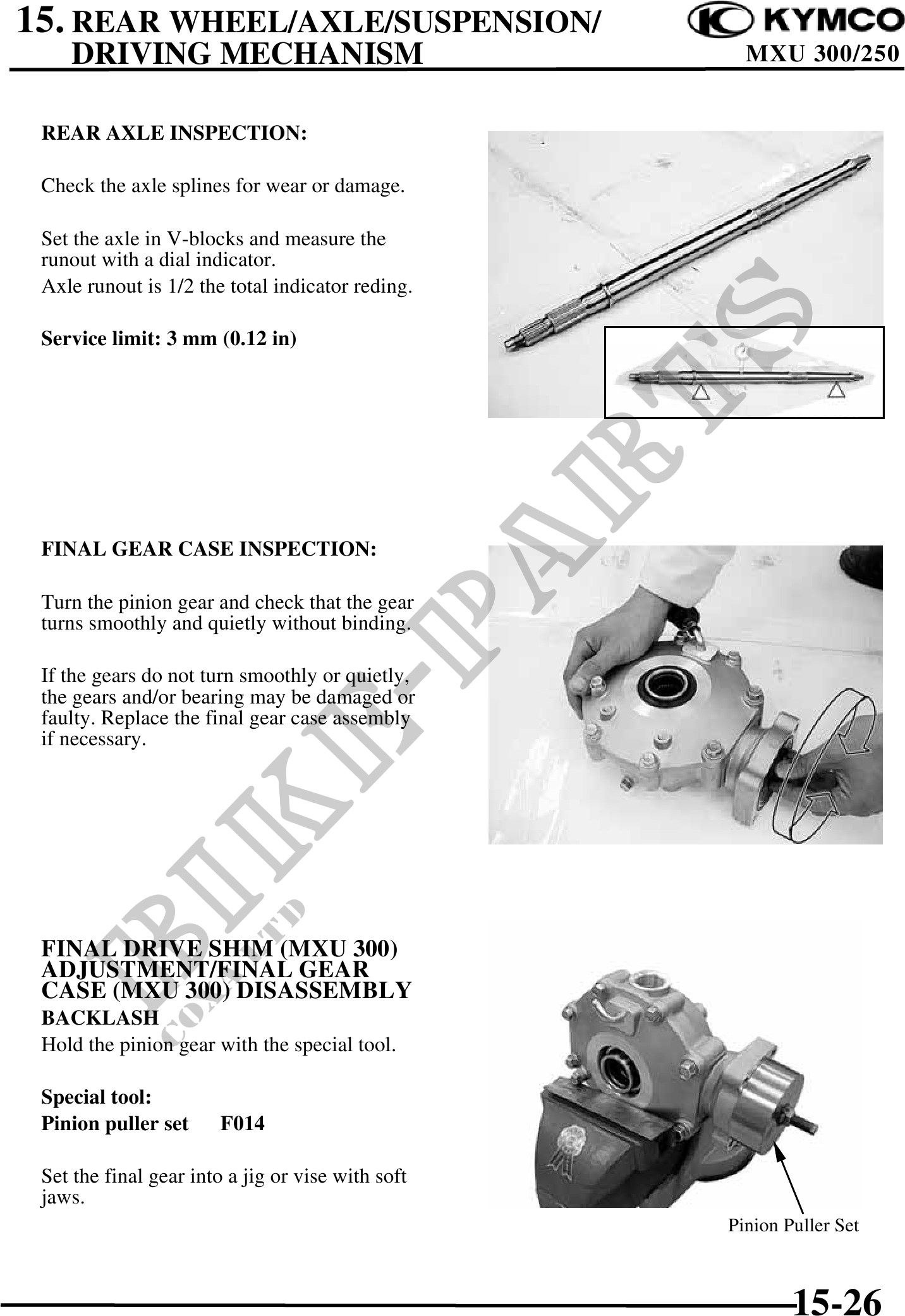

FINAL DRIVE SHIM (MXU 300)

ADJUSTMENT/FINAL GEAR

CASE (MXU 300) DISASSEMBLY

BACKLASH

Hold the pinion gear with the special tool.

Special tool:

Pinion puller set F014

Set the final gear into a jig or vise with soft

jaws.

Pinion Puller Set

15-26