Ihr Warenkorb

| Beschreibung | Teile-Nr. | Anzahl |

|---|

5. FUEL SYSTEM MXU 300/250

ASSEMBLY

Install the slow jet.

Install the needle jet, needle jet holder and

main jet.

Install the throttle stop screw and air screw

Install the spring, diaphragm and O-rings.

· When installing the air screw, return it

to the original position as noted during

removal

· After the carburetor is installed, be

sure to perform the Exhaust Emission

Install the float valve, float and float pin.

FLOAT LEVEL INSPECTION

Turn the carburetor upside down so that the

float will go down to make the float valve

contact the float valve seat.

Then slowly tilt the carburetor and measure

the float level with the float level gauge

while the float pin just contacts with float

valve.

Float Level: 14.8mm

When adjusting, carefully bend the float pin.

Check the float for proper operation.

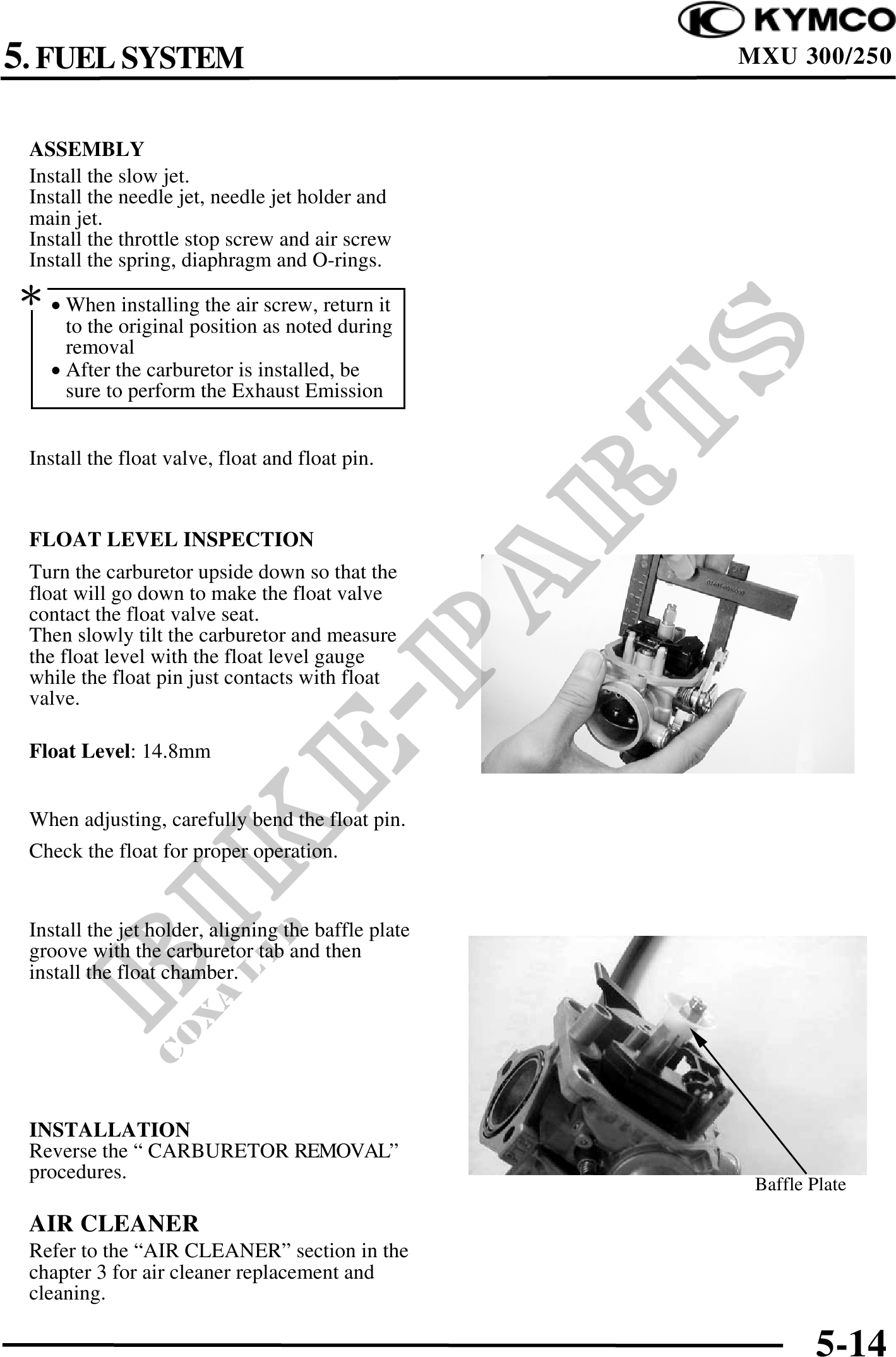

Install the jet holder, aligning the baffle plate

groove with the carburetor tab and then

install the float chamber.

INSTALLATION

Reverse the " CARBURETOR REMOVAL"

procedures.

Baffle Plate

AIR CLEANER

Refer to the "AIR CLEANER" section in the

chapter 3 for air cleaner replacement and

cleaning.

5-14